Today in this guide we will be going over the best tips on how to use a ratchet strap in 2022. This blog includes full step-by-step instructions on how to thread a ratchet strap, how to tighten a ratchet strap, how to loosen a ratchet strap and a combination of expert tips from the pros! Let’s begin!

What are Ratchet Straps?

Ratchet Straps are one of the most common types of tie-down straps that are designed for securing various sizes and weights and cargo for transport. Ratchet Straps are available in 1-inch wide, 2 inches wide, 3 inches wide, and 4-inch wide variants and are available in many different lengths of webbing and hardware to fit your securement needs best. Ratchet Straps are made with polyester webbing that stretches very little and provides great amounts of strength and durability to ensure that your cargo does not move out of place once properly secured.

Ratchet Straps are made with a Ratchet Hardware mechanism that flows in one direction allowing you to tighten your strap much tighter than the traditional hand strength that is used in cam buckle straps. There are many different types of end fittings such as popular E Track Fittings, S Hooks, Wire Hooks, Endless Loops, Snap Hooks, D Rings, and many different tie-down hardware options.

If you don’t see exactly what you are looking for chances are we can custom make the perfect strap that fits your application needs. If you need it completely custom made or this blog is unable to help answer your questions on ratchet strap give our friendly experts a call at 800-483-2189 or by using our online contact us form located at the top of the website. Our team looks forward to assisting you further with all of your cargo securement needs.

How use a Ratchet Strap Instructions

1. Start by opening the ratchet handle hardware and align the opening slot of the ratchet is pointed upwards.

2. From the bottom of the ratchet hardware slowly thread the webbing through the slot in the center of the spool of the closed ratchet.

3. Next pull the webbing through and remove the excess slack or loose webbing to make a firm but not tight webbing.

4. Start ratcheting by raising and lowering the ratchet handle to tighten the strap by removing excess slack to hold your cargo into place. Make sure your cargo securement with the ratchet strap is snug, but not too tightly that it could cause damage to the cargo you are securing.

How to Loosen a Ratchet Strap Instructions

1. To release the strap pull and hold the release tab on top of the ratchet assembly to override the ratcheting function. This will allow you to open the ratchet hardware.

2. Open the Ratchet hardware until it is completely open and the ratchet is laying completely flat.

3. Grab the polyester tie-down webbing from the nonfixed side and begin to pull the webbing out of the ratchet to release.

4. When you are done removing the webbing from the hardware pull and hold the release tab on top of the ratchet to close the ratchet for its next use.

How to Store a Ratchet Strap In-Between Uses

• Keep the Ratchet Strap out of direct sunlight as the sun’s ultraviolet rays can weaken or cause discoloration to the tie-down webbing over time.

• Do not store ratchet straps in areas that have extreme moisture or dampness as it could lead to mold or mildew which could cause the straps to weaken or become in need of replacement over time.

• Avoid any areas where sharp edges could cause cuts, webbing to fray, or direct damage to the webbing on the strap. Something as simple as a toolbox’s corner can cause friction burns over time causing the webbing to weaken or become destroyed.

• Help keep ratchet straps lasting longer by keeping the straps out of the wind and neatly organized in between uses by using rubber bands, ziplock bags, or old socks to keep them neatly organized in-between trips.

You can view our full guide on how to store ratchet straps properly by clicking HERE.

How to Untangle a Jammed Ratchet Strap

If you notice your Ratchet Strap has become jammed or tangled inside of the ratchet mechanism hardware you will want to completely stop what you are doing with the strap. Analyze and look over the tie-down strap to see where the strap is stuck or tangled before making your next move as you could quickly cause the situation to become worse.

If you are unable to get the tangled webbing out of the ratchet hardware you may need to remove the bolts on the side of the ratchet hardware. If you do remove the bolts on the side you will want to make sure the sides of the ratchet hardware are correctly tightened and inspected so that they are safe to use before the next use.

You will want to make sure that you are NOT using any sharp objects such as a screwdriver or metal object as it could cause damage to the webbing. If it is possible we recommend you attempt to untangle the webbing using your hands as the risk of causing damage to the webbing during the process is greatly reduced. This may take some time to untangle the webbing and this process can be different for everyone depending on where the strap has become tangled.

Tips to Prevent Ratchet Straps from Becoming Jammed

• Do not overtighten your ratchet strap when tightening your straps. 4-to-5 clicks are more than enough for most circumstances.

• When storing the straps after every use store the straps properly. Throwing the straps loosely in the back of a truck bed can cause them to become tangled between uses and could also cause the webbing to become damaged if the straps are rubbing against sharp edges. You can fix this by storing the ratchet straps in various ways as discussed in our How to store Ratchet Straps Blog post.

• Make sure to pull the webbing tight by using hand force before tightening by using the ratchet hardware. This helps to reduce the chance of excess tie-down webbing becoming jammed inside of the ratchet.

How Many Ratchet Straps Do I Need?

When securing cargo you should always use at least four tie-down straps at a minimum for most normal cargo securement applications. This is especially true for cargo that is larger in physical size or heavier in weight. When securing cargo you will want to plan for the worst when it comes to cargo securement as you never know what could happen along the way to the next destination.

It only takes a sharp corner, a sudden stop, fast acceleration, sudden lane change, or another motorist cutting you off to cause the cargo to shift out of place. You can help play your part in keeping the cargo and others on the roadway safe by using straps at every edge of the cargo.

For example, a vehicle should be secured from each of the four tires to prevent the vehicle from moving during transit. This also helps if a strap were to fail on the way to the next destination from any of those things you can never plan for during a drive. It only takes a strap coming loose or a strap to break during transit from excess stretching to jeopardize your entire cargo load.

That’s why using extra straps and securing from numerous securement angles to help play a part against load shifts is crucial for any cargo securement. The general rule of thumb in the trucking industry and professional cargo securement industry is to always use more straps than required when you are transporting valuable, oddly shaped, or heavy in weight cargo. It is never a bad thing to use too many straps but there is a real issue with using too few ratchet straps.

If you ever feel unsure or unsafe about transporting cargo it’s always a good idea to add heavier duty working load limit straps or increase the number of straps you are using to secure the cargo when possible. It’s always critical for anyone transporting cargo to know the weight of the cargo itself and the working load limitations of your straps as well. You should never put yourself in a situation where you are exceeding the working load limit of the strap as it is unsafe to do so and working load limits were created to keep you safe.

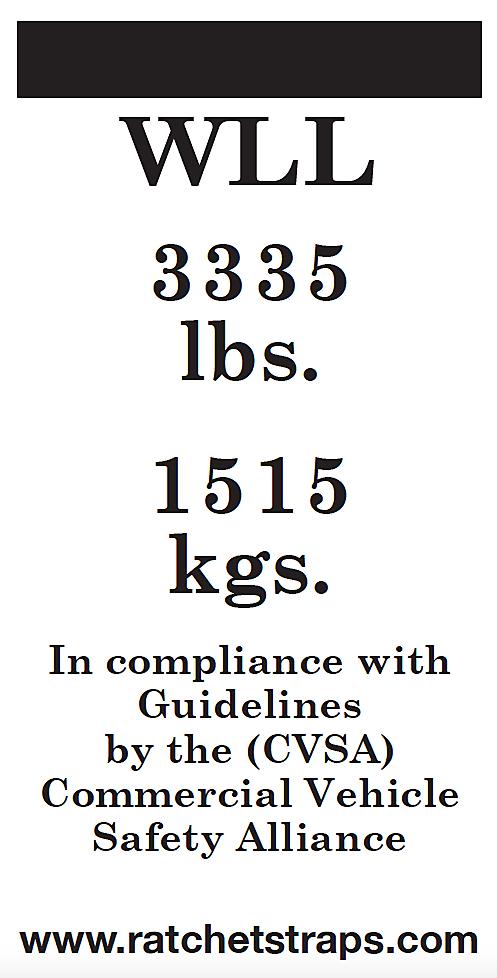

What is a Working Load Limit?

Working Load Limits are determined by taking the ultimate amount of breaking strength to failure and diving the number by three. For example, a 10,000 lbs breaking strength strap would have a 3,333 lbs Working Load Limit. Although the strap may not fail till 10,000 lbs of force you should always go by the 3,333 lbs working load limit in this circumstance.

It’s an important reminder that working load limits were put in place to keep you safe while transporting cargo down the road. If you are second-guessing yourself if the load is safe to transport with the number of straps or strength of the straps you add more straps or change to a heavier duty working load limit strap to stay safe.

Remember, there is never an issue with adding too many straps, but there is a real problem with not using enough straps to secure loads. Another helpful tip is to make sure the straps you are securing your load with are in different areas of the cargo to help against a sudden brake, a sudden change of lanes, or debris in the road causing a swift motion to avoid.

There are big fines, penalties, and potential jail time in the United States for failing to comply with the DepartmentTransportations’ons’ general guidelines while transporting cargo on the roadways. Become familiar with these rules by checking out your state’s cargo securement general guidelines. You can view our full guide on How to understand Working Load Limits.

Shop our Popular Ratchet Straps

Frequently Asked Ratchet Strap Questions

What do I do if my Ratchet Strap Becomes Tangled? – If at any point your ratchet becomes tangled you will want to stop what you are doing physically and look over your tie-down strap to see where it is stuck. By continuing to add force to the tie-down webbing you could be essentially tightening the tangled ratchet even further. If you are unable to get the tangled ratchet strap out, you may need to remove the bolts on the Ratchet to release the webbing and get the webbing untied using pliers or bolts.

How Do You Keep Ratchet Straps From Loosening? – The best way to keep Ratchet Straps from loosening is to make sure that the Ratchet handles on the Ratchet Straps are completely closed before transporting any cargo. If the Ratchet is not completely closed there is a high chance that the strap could fail during transport. Another way to make sure that your ratchet straps do not come untightened or unloosened during the transportation is to make sure you are always using at least four or more tie-down straps to use more fail safes. A fail-safe is an extra layer of protection that is used to keep you safe. Although you may be able to get away with fewer straps, if a strap were to fail you would be okay.

What type of webbing does Ratchet Straps use? – Ratchet Straps use a well-tested polyester tie-down webbing blend that can provide great strength with a very little amount of stretching. The webbing provides great durability outside in the elements with various weather elements.

What Should I Do if My Ratchet Strap Becomes Damaged? – If you notice any defects in your ratchet straps hardware or tie-down webbing please stop using the strap immediately. It is unsafe to do and using the strap after it has become damaged could cause damage to your load, injuries, or possible fines. This is why it is critical to inspect your ratchet straps before and after every use to ensure the quality of your straps is safe to use. If only one side of the strap is damaged chances are you can purchase a replacement strap to make your old damaged strap in like-new condition by reusing the side of the strap that is still in good condition. You can learn more about our replacement strap capabilities by giving our experts a call at 800-483-2189 or by using our online contact form located at the top of the website if you prefer to communicate through email.

What Is The Best Way To Find Out How Long I Need My Ratchet Strap Length? – The best way to find out the length of the tie-down webbing that you need for your ratchet strap is to use a piece of string to wrap around the cargo or estimation of how large the cargo is going to be and then measure the piece of string. This is a cost-efficient way to get a very close to exact estimate of how much webbing is needed for your cargo securement. Once you have the length that is needed the next step is to make sure you order more than your application needs rather than potentially less. The general rule of thumb is normally to purchase 2 more feet of webbing than is needed to provide yourself with extra wiggle room for different cargo securement applications.

What If I Need A Custom-Made Ratchet Strap? – If you don’t find exactly what you are looking for online or on our website, odds are we can create a custom-made to order strap with options that fit you best. No matter if you need a custom length, color, company stencil, or a hardware combination that you don’t see listed odds are we can custom make the perfect strap for an additional price. If you are interested in learning more about our custom-made strap capabilities give our experts a call at 800-483-2189 or by using our online contact us form.

What are the added benefits of Heavy Duty Webbing? – Heavy-duty webbing provides ratchet straps with extra durability against potential cuts, burns, and added protection against the elements. In our experience when Ratchet Straps tend to break after long repetitive use the webbing is almost always the cause of the strap breaking well before the hardware breaking. In most circumstances, the heavy-duty webbing when paired with corner protectors can help your ratchet straps last for longer without the need to replace the straps as often. Our 1-inch wide heavy duty webbing features a 6,600 lbs breaking strength and is the strongest 1-inch wide tie-down webbing in the industry and is made with extreme strength and durability.

Do you need to use Corner Protectors with Ratchet Straps? – Although having corner protectors is not required to secure cargo with ratchet straps we strongly urge customers to consider it if the cargo you are securing has sharp corners. Sharp corners are among one the leading reasons why ratchet straps fail and corner protectors help to provide added protection to help make your cargo securement safer and help your tie-down straps to last longer.

What are the different types of Ratchet Hardware? – You can view our full selection of different ratchet hardware HERE. Ratchet Hardware can vary by size, metal, color, grip, and coating on the ratchet hardware handle itself.

What are the Differences Between Working Load Limit and Breaking Strength? – Breaking Strength is different from working load limits as the breaking strength is used to help determine the working load limit. For example, a strap that fails at 10,000 lbs breaking strength and dividing it by three would give you 3,333 lbs working load limit. The reason behind the division by three numbers that are used to determine the working load limit is to keep your straps from becoming overloaded, allowing a barrier of wiggle room for things to go wrong, as well as not allowing a broken strap to jeopardize your entire cargo securement.

What are the best Ratchet Straps for Water Applications? – When it comes to water or marine type of applications there are a few things you should do differently when picking webbing and hardware options. Firstly, normal hardware is prone to rusting over time due to the materials that are used, this may speed up when used in saltwater applications. To help prevent the ratchets from rusting you will want to use a stainless ratchet that slows the spread of rust and is ideal for saltwater applications especially. When it comes to webbing you will want to avoid darker colors of webbing such as red, blue, purple, or black webbing. These webbings over prolonged use in water can cause the webbing to slightly bleed out so it’s ideal for marine applications to use lighter colors such as white webbing.

How do Endless Loop Ratchet Straps Work? – Endless Loop Ratchet Straps are as the name describes endless loops without any form of hardware. These straps are mainly used for securing cargo together, bundling, treestands, slacklines, or bundling cargo to a skid for transport.