Today we will be going over the ultimate truck straps guide with information from the tie-down experts for the trucking industry. Learn how the different types of truck straps play a part in cargo securement and some of the most commonly asked questions about trucking straps from the experts.

As 2019 continues to become an ever-growing era for online shopping part of the ever-growing demand to keep websites shipping orders is being able to transport them safely to the customer’s doorstep. As margins become more competitive on a national scale for online orders, the shipping and transportation industries are receiving more and more pressure to have no room for error.

When shipping in the United States you are under very strict transporting guidelines from the Department of Transportation to make sure you are following the rules and regulations that are put in place to keep motorists safe. Motorists who share the roads with trucking fleets and other professional haulers are under strict time frames to get the packages to the customers as quickly as possible. This can often make the difference between reputable transportation companies and those who may take shortcuts in order to save costs by jeopardizing your cargo and the safety of other motorists.

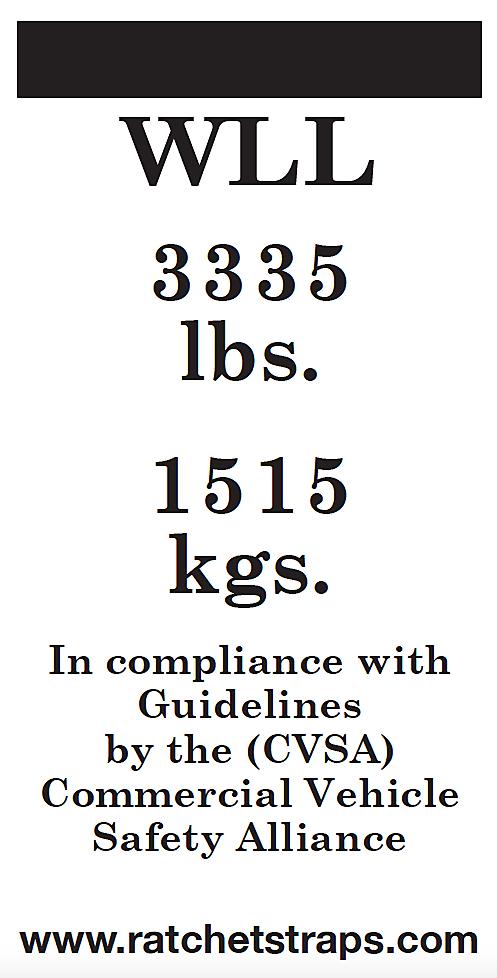

So what can you do to help fix this major problem? You can play your part in helping to fix unsafe cargo being transported around the United States by using reputable tie-down straps that are rated to secure your load safely without going over the recommended Working Load Limit. The Working Load Limit (WLL) is used to keep motorists and cargo arriving safely to its destination by using 1/3 of the breaking strength, or in other words the ultimate amount of strength before breaking.

As you never want to reach the ultimate amount of strength before breaking this allows for some overhead if you were to slam on your breaks, or if you were to have a sudden lane change due to another motorist or debris in the roadway. Cargo Straps for trucks were invented to make sure the cargo on the trucks arrived safe and to help reduce the amount of debris that was on the side of the roads from unsafe securement methods.

The next time you are driving down the highway count how much debris you can spot on the side of the road within a 10-mile period. You will notice there is a real problem on the roadways for both amateur and professional truck drivers using improper securement practices that could result in real danger.

Some companies will buy cheap ratchet straps in order to help to reduce prices for what may seem like the same product they are purchasing. However, most companies will instantly realize the straps they bought were cheaply made, thinner tie-down material, hooks that seem to bend, or in some cases snap after just several uses. This causes companies to then purchase reputable cargo straps for trailers on top of the previous purchase of cheaply made ratchet straps that may seem worthless after a near accident.

The number one method that trucking companies can do to reduce costs in tie-down straps is purchasing reputable safe tie-down straps that last for years. On average reputable cargo, straps can last around 3 years if properly stored and not around sharp edges that could cause friction or burn areas on the tie-down webbing. This is one of the best long-term investments truck drivers can make in reducing costs and potential insurance claims from unsafe cargo securement.

Why were Working Load Limits put into place?

• Before working load limits were put into place cargo could often be found spread throughout the roadways along the sides of the road and in the ditches running parallel with the roadways.

• Working Load Limits help to prevent other motorists and professional shippers from becoming injured by traveling down roadways by providing a safety net or some room for error to occur.

• Working Load Limits were determined to be the safe amount of allowance between safe to use and could potentially break by using numerous different scenario testing by the Department of Transportation (DOT).

• Working Load Limits are different for every strap, so it’s an important reminder to make sure to always double-check your working load limit tag to make sure the strap that you are using to secure cargo is rated to secure the weight of the cargo you are transporting. You can often find a wide variety of different working load limits between Ratchet Straps, Cam Buckle Straps, and E Track straps depending on the assembly working load limit of each.

Some Helpful Truck Strap Tips

• The number one tip you can follow when you are using the working load limit to keep safe is to never exceed the working load limit recommended weight. It is much cheaper to buy a correctly rated tie-down strap to keep your cargo secured, instead of filing costly insurance claims, lost customer relationships, and costly fines. Working Load Limits (WLL) can also be known around the industry as weight capacity. An example of a Working Load Limit is a load that requires a capacity of 2,000 pounds. You will want to use at least 2,000 working load limit in straps used in pairs to cover this load. However, you will want to allow for some wiggle room in case of a strap fails or somehow comes untied the cargo does not fall off. So a good rule of thumb is to go at least 500 pounds or 1,000 pounds over the working load limit of the cargo you are securing.

• Following the tags rating. Although Straps have a Working Load Limit some drivers may refuse to abide by the tags working load limit and can easily be cited if they do not use enough tie-down straps to accommodate the load. Generally, you will want to secure your cargo from four different securement points in different areas of the cargo to help provide a balance for the load to prevent tipping over, quick braking, or sudden lane changes from damaging or destroying your cargo.

• Inspect your tie-down straps before every use and check for any frayed webbing, burn defects, excess webbing inside of the ratchet, or any weather such as sun damage or mold and mildew that could weaken the strength of your tie-down straps.

• In the tie-down industry more is always better. It is way better to have too many tie-down straps than too few. If you aren’t sure the load you are securing is safe to transport, you may want to consider using a few more tie-down straps even if it doesn’t look like some of the pro’s tie-down securements.

• The most common types of Truck Straps by far are Winch Straps, Ratchet Straps, and E Track Straps. However, endless straps have become one of the most popular straps for truckers as you can fasten cargo to itself to save space or keep cargo secured on a pallet in the back of a tractor-trailer.

• Remember to tie your loose ends so the straps are flapping in the wind as you are going down the road.

• Lastly, the number one tip that anyone can follow is to remember to check and then re-check after several miles down the road to make sure that your winch straps or ratchet straps are secured tight enough to keep your load secured. Once you have arrived at your destination it is equally important to make sure that you are storing your straps in a dry area away from any sharp edges that could cause friction or minor burns to your polyester tie-down webbing.

How Long Do I Need A Truck Strap?

When determining the length of tie-down webbing that you need to fit your application you always want to make sure you have extra webbing opposed to not having enough webbing. If your application requires 15 feet of webbing you could get away with 16 feet of tie-down webbing, however, it might be best to go ahead and get 20 feet long tie-down straps to have a little extra wiggle room for oddly shaped cargo. Buying excess polyester tie-down webbing allows you to prepare for error if you receive cargo that isn’t in the shape of a box or pallet.

If you aren’t exactly sure what length of webbing you need for your cargo securement needs one of the best ways to tell is to use a piece of yarn or string that you find lying around the house to measure approximately how long you need it to be. Once you have a general idea of how long of webbing you will need you can measure it with a tape measure to determine the length of webbing that is ideal with the proper working load limit (WLL) for the weight of your cargo. This has become one of the best-known truckers’ tips for finding the length of webbing that you need to fit your load through professional trucking fleets and dry vans.

The Different Types of Truck Straps

Winch Straps – winch straps are the most common tie-down strap that is used as truck straps for the flatbed trucking industry for the heaviest loads. Winch Straps are not like your average ratchet straps, as the ratchet alone on winch straps weighs over 8 pounds alone. Winch Straps come in 3 inches and 4-inch wide polyester tie-down webbing that creates a combination for securing some of the heaviest loads on the road. Although these straps are rated for much higher working load limits than traditional ratchet straps you should always use at least four tie-down straps to help distribute the weight of your cargo to be prepared for sudden lane changes or load shifts that could occur.

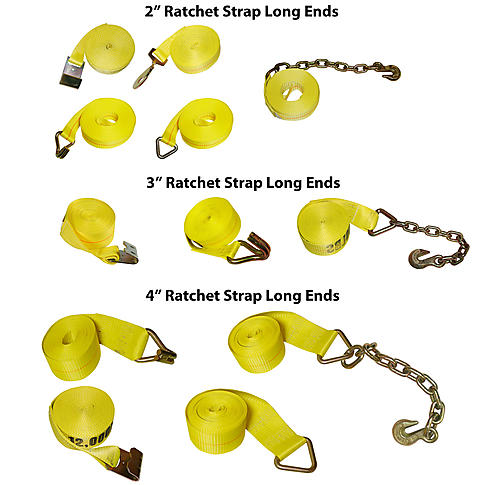

Ratchet Straps – ratchet straps is by far the most popular type of tie-down straps on the market and are used for a wide variety of different tie down cargo control securement. What makes Ratchet straps such a great tool for the professional trucking industry is the ability to custom make the perfect ratchet strap with a wide variety of different hardware, hooks, length of webbing, the width of polyester tie down webbing, and a complete line of different stenciling capabilities to make the strap exactly how you want it. Ratchet Straps are available in 1 inch, 2 inches, 3 inches, and 4-inch polyester tie-down webbing that creates a wide range of working load limits to fit your cargos correct working load limit rating that you need in order to stay safe.

Endless Loop Straps – endless loop tie-down straps is one of the newer types of tie-down straps over the last decade for the professional moving van and trucking fleets and are used to secure cargo together. Unlike traditional ratchet straps or winch straps, these straps are able to secure together without any hooks or attachments to create bundling to save space or keep cargo secured on top of a pallet as a breeze. Endless Straps provide a great method of keeping cargo secured together to utilize the available space inside of the trailer that may not be previously used, which could easily result in more trips being needed in order to get the same job done.

E Track Straps – e track straps have become popular to use with E Track rails that are run along the walls and flooring of tractor-trailers to be able to be attached from numerous different securement points. This is one of the main reasons that make e track straps a great tool as e track rails have between 15 to 60 different securement points depending on the length of rails. Not only can this be a great way to secure cargo from different angles, but e track can also be run vertically allowing for even more space inside of the trailer to be used to result in making fewer trips, quicker securement times, and saving trucking fleets money.

Cam Buckle Straps – cam buckle straps is one of the more unique tie-down straps as they are secured as tightly as you can pull by using the strength of your hands. This is a great alternative to Ratchet Straps as it is extremely unlikely that you manage to overtighten cargo causing damage. Cam Buckle Straps have become the industry standard for antiques, sensitive or fragile cargo, and surfaces that could easily bend when using ratchet straps that can easily be over tightened. Cam Buckles have a wide variety of different hardware such as S Hooks, Wire hooks, E Track Fittings, and other attachments to create a securement that works for your application needs. We have a wide selection of different Cam Buckle Straps on our website that can be found here. RatchetStrapsUSA also has the capabilities to custom make just about any kind of strap you need for an additional price.

Recovery Tow Straps – recovery tow straps are some of the most commonly used straps for recovering vehicles that have wrecked or need to be towed out of a tight spot such as water, snow, sand, mud, or other road debris. The main difference between traditional straps and recovery tow straps is the tow straps are used for towing and to reduce the stress on your strap and vehicle you want as much stretching as possible without needing to worry about the strap breaking. This is the reason behind tow straps using Nylon webbing that stretches greatly compared to polyester tie-down webbing that stretches very little. Most professional tow truck drivers use 2 ply tow straps as they are able to get the job done numerous times safely without needing to worry about weakening over time that 1 ply tow straps may have.

Truck Strap Accessories

Corner Protectors – corner protectors is one of the best ways to protect your investment by purchasing truck straps. The way that corner protectors work is extremely simple they are placed around sharp corners around the trailers or the cargo that you are securing in order to protect against edges that could cause damage or friction that could cause burn marks that could ultimately weaken your tie-down straps. They are available in varieties such as heavy-duty, heavy-duty steel, and wool strap protectors for vehicles to prevent scratches.

Chain V Bridles – chain bridles is one of the best ways to use in conjunction with recovery tow straps for applications that may require more strength. Tow chains are used for towing and should never be used to recover a vehicle that is stuck. However, if you are on a flat or road surface chain v bridles is a great way to pull a vehicle, ATV, or UTV to a new location.

Ratchet Straps Bag – storing ratchet straps in a clean, dry, and protected from the sun’s rays while remaining organized for professional truckers can be quite the hassle. We have made several different Ratchet Straps USA duffle bags at a very affordable price point to help tie-down straps last longer. If you are interested in more information about our different ratchet straps bags they can be found here.

Winch Track – winch track is one of the flatbed trucking fleets’ most needed accessories that allows truck drivers to quickly secure cargo by tightening the winch track to tighten the winch straps that are run alongside the rails of the trailer. Truck drivers can easily slide the winch track into the preferred location for the cargo securement and accessibly secure cargo in a matter of minutes. This helps to keep the truck drivers remain on the road quicker resulting in more miles per day from the drivers.

Most Popular Truck Straps

Truck Strap Frequently Asked Questions

Question: Will my Truck Straps Stretch?

Answer: Truck Straps such as Ratchet Straps, Endless Straps, Winch Straps, and tie-down straps that are used to secure cargo stretch very little to reduce any chance of the cargo ever becoming unsecured during transport. Truck Tie Down Straps that stretch more are typically made from a nylon webbing blend that is made to stretch to reduce stress on vehicles and the tow strap from receiving damage.

Question: How many truck straps do I need?

Answer: You will want to make sure if you are securing cargo to use at least four tie-down straps for most cargo securement, however, if you don’t feel comfortable only using four tie-down straps you can always use more to give reassurance of your cargo will arrive safely. No matter if you are securing cargo or towing a vehicle using a recovery strap you will always want to make sure you are using a strap that is safely rated for your application.

Question: What are USA Made Truck Straps?

Answer: USA-made Truck Straps are truck straps manufactured in the United States. The main difference between cheaper tie-down straps that may be manufactured inside of countries such as China and straps that are manufactured inside of the United States is quality control. Although straps over the last decade have become greatly better than in previous decades in terms of quality you may notice the slightly higher quality in USA tie-downs due to strict guidelines put in place by the Department of Transportation (DOT). As USA-made uses labor rates that are higher than other countries you may find that USA Truck Straps may come at an additional price point compared to normal tie-down straps.

If you have any further questions regarding truck straps and how they can help your trucking fleet become safer please give our experts a call at 800-483-2189 or by using our online contact form that can be located here.